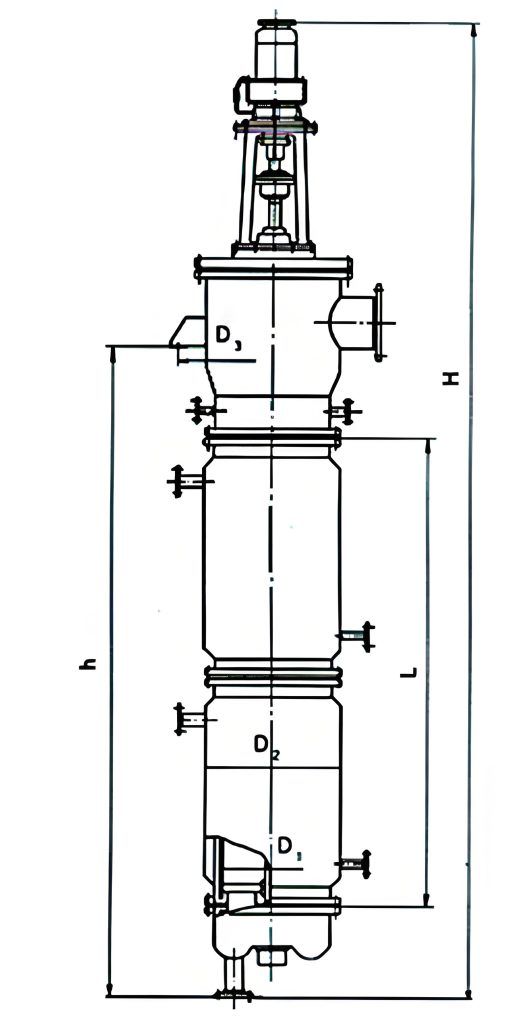

Rotary film evaporator

Scraper type thin film evaporator is an efficient evaporation and distillation equipment that uses high-speed rotation to distribute liquid into a uniform thin film for evaporation or distillation. It can also perform deodorization, defoaming reactions, heating, cooling and other unit operations, and can be widely used in industries such as pharmaceuticals, food, light industry, petroleum, chemical industry, and environmental protection in China and the West.

This equipment adopts a centrifugal sliding groove rotor, which is a new structure evaporator in foreign countries. It can form a thin film even at very low flow rates. The sediment in the treatment liquid attached to the inner wall surface of the cylinder evaporation section can be quickly removed by the movable scraper. Compared with the fixed gap scraper evaporator, the evaporation capacity can be increased by 40-69%. It has the following performance and characteristics:

- High heat transfer cofficient value, large evaporation capacity, evaporation intensity can reach 200kg/m2. hr, and high thermal efficiency.

- The heating time of the material is short, about 5 to 10 seconds, and it works under vacuum conditions, which is more advantageous for heat sensitive materials, keeping various components from decomposing and ensuring product quality.

- It can adapt to a wide range of viscosity changes and handle both high and low viscosity materials. The material viscosity can reach up to 100000 centipoise (CP).

- Changing the rotation direction of the scraper groove can adjust the maintenance time of the material in the evaporator.

- The inner wall of the evaporation section cylinder is precision bored and polished, making the surface less prone to coking and scaling.

- Easy to operate, easy to adjust product indicators, and can be controlled for continuous production under closed conditions.

- The equipment has a small footprint, simple structure, easy maintenance, and easy cleaning.

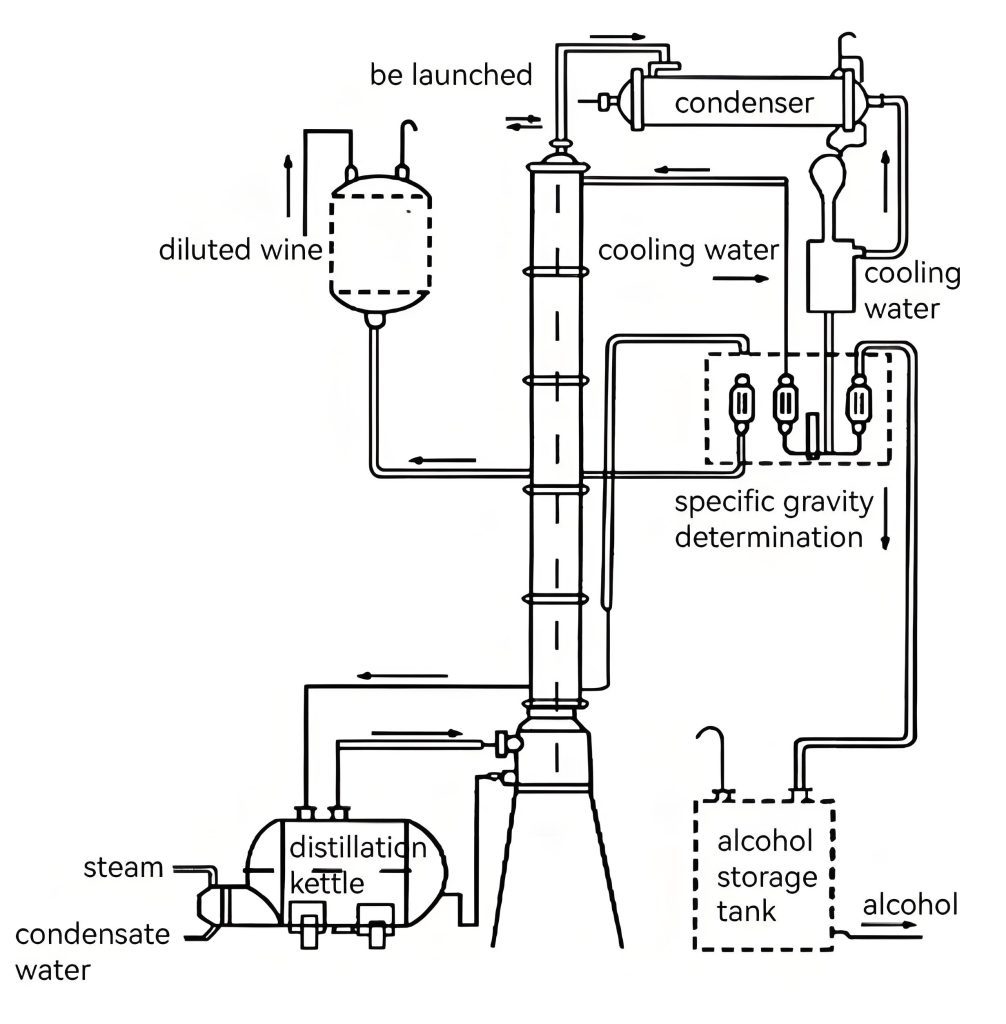

Effect diagram of using thin film evaporator

| Project model | LG0.8 | LG1.5 | LG2 | LG2.5 | LG4 | LG6 | LG10 |

|---|---|---|---|---|---|---|---|

| Heat exchange area (㎡) | 0.8 | 1.5 | 2 | 2.5 | 4 | 6 | 10 |

| Steam pressure (MPa) | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Vacuum degree (Kpa) | 70 | 70 | 40 | 70 | 70 | 70 | 70 |

| Evaporation rate (kg/h) | 80 | 150 | 200 | 250 | 400 | 600 | 1000 |

| Energy consumption (kg/h) | 168 | 315 | 320 | 525 | 840 | 1260 | 2100 |

| Motor power (KW) | 1.1 | 1.5 | 2.2 | 2.2 | 4 | 5.5 | 11 |

| Rotational speed (rpm) | 110-130 | 110-130 | 110-130 | 110-130 | 110-130 | 110-130 | 110-130 |

| Equipment height (mm) | 2500 | 3295 | 4000 | 4100 | 5180 | 5800 | 7800 |

PRODUCT DISPLAY

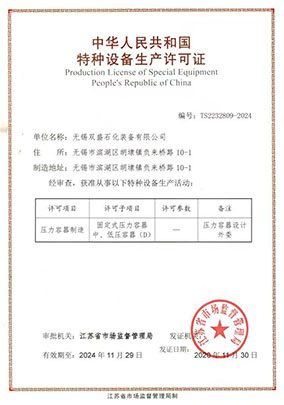

CERTIFICATIONS

WHY CHOOSE US

Effective technical support and high quality products

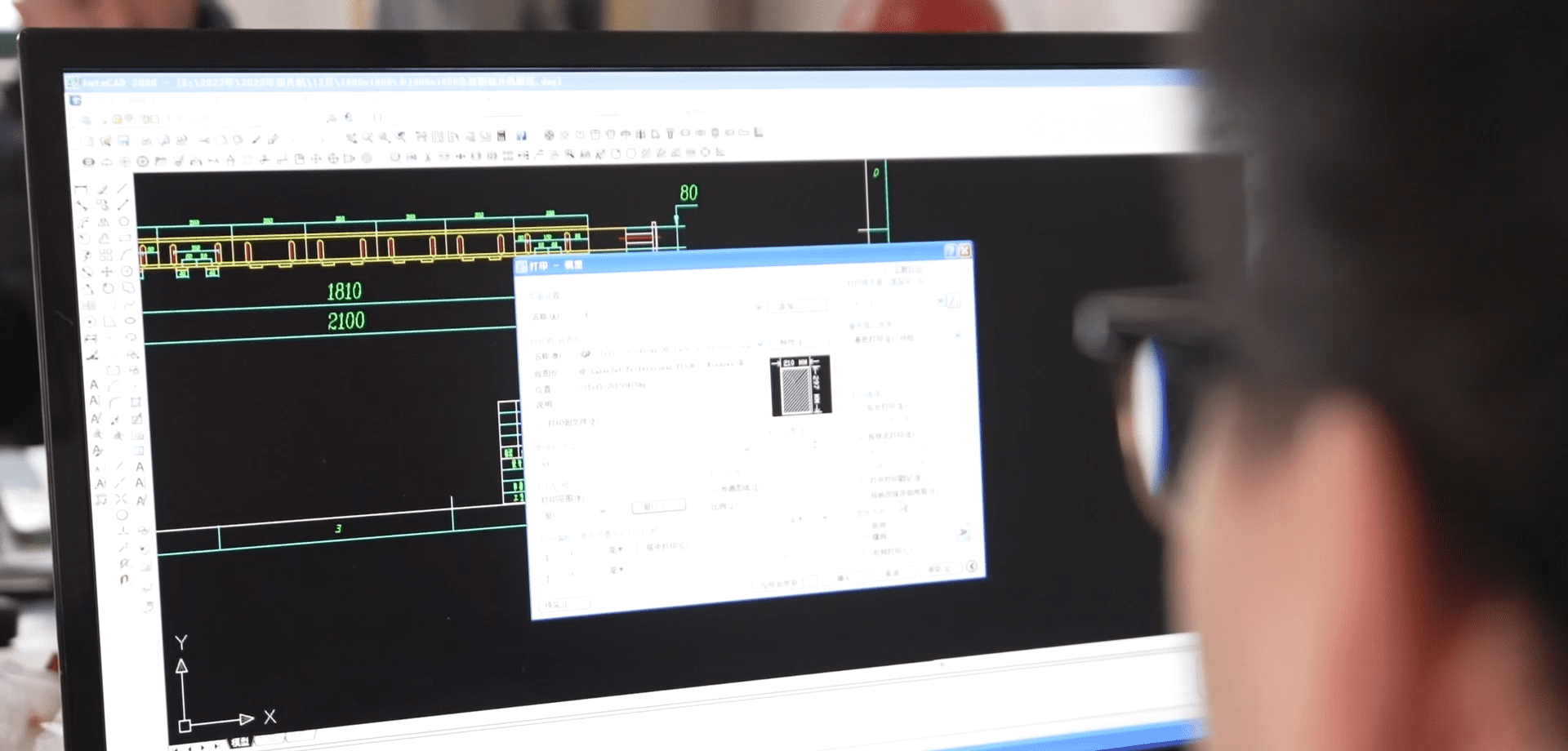

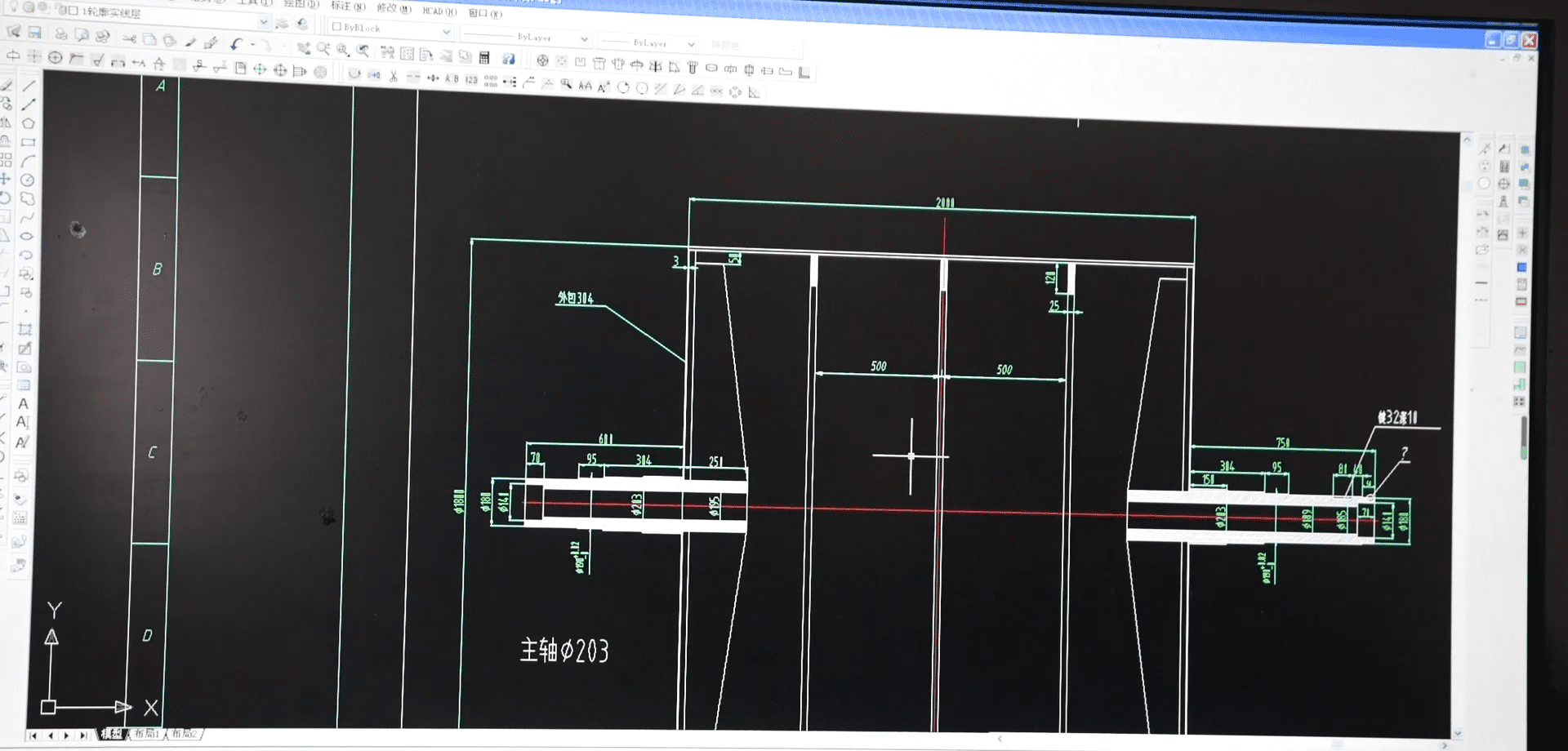

we have heavily invested in technological innovation. Our team includes 19 technical designers, and we use SW6-98 calculation software to ensure standardized and regulated design and drawing processes.

As a certified manufacturer authorized by the Quality and Technical Supervision Bureau and Space Ministry Of China, we are qualified to produce Class I and II pressure vessels and chemical equipment. In 2012, we obtained the Class I and II (A2 grade) Pressure Vessel Manufacturing License (No. TS2210F48-2016) issued by the General Administration of Quality Supervision, Inspection and Quarantine. Additionally, we earned the 2000 edition Quality System Certification from the China Classification Society in 2009.

Our Shuangsheng Strength

Originally founded in 1991 as Wuxi Xuelang Chemical Heat Exchange Equipment Factory, the company expanded and rebranded as Wuxi Shuangsheng Petrochemical Equipment Co., Ltd. in 2009. We occupy a 30,000-square-metre facility, with 3,000 square metres dedicated to office space, and have a registered capital of CNY 28 million . Our team consists of over 50 employees.

We specialize in the production of various pressure vessels, including slicers, flakers, drum flakers, condenser crystallizing slicers, and spiral plate heat exchangers. Each year, we supply customers with more than 200 flaking machines and over 20,000 square metres of heat exchange equipment, along with hundreds of custom non-standard and reaction equipment units.

strong customized ability and relia lbe solutions

Besides the rotary drum flaking machine and rotary drum cooling machine, we also produce pilot plants which offers you the investigation of the feasibility of a desired process, this approach contributes significant cost savings in the year of operation to come.

PARTNERS

TECHNOL OGICAL INNOVATION INTEGRITY AND PRAGMATISM

By accumulating more and more experiences and technical research, we have been striving for innovation of process solutions and has an excellent capabilities to solve all your required technical problems. We will keep making new contributions to the product performance and quality.

With wide range of our product applications, we are ready to be your reliable partners in the future.Our company is built on the values of “integrity, dedication, and a people-first approach”, with a commitment to “creating value for our customers”. We warmly welcome partners from all sectors, both new and old, to discuss cooperation opportunities and work together toward a prosperous future.

Contact us:Daisy

Cellphone:+86 13771159885

Whatsapp/Wechat:+86 13771159885

Email:sales@wxsssh. com

Address:No. 10, Negative Laiqiao Road, Hudai Industrial Park, Binhu District, Wuxi City in China